Liquid vs Powder Solvent Dyes: Which type is right for your application?

ShareThe world of solvent dyes can be a confusing place and, with an array of different formulations, product variations, and manufacturers, choosing an appropriate dye is not always easy. In this article, we take an objective look at the differences between two major types of solvent dye, liquids and powders, to help you make an informed choice about which product is right for you.

What are ‘solvent’ dyes?

Dyes have been around for a while. In fact, natural dyes have been around since the stone age (literally), with the earliest known dyed flax fibres, found in a prehistoric cave in Georgia, dating from 34,000BC.

Dyes were produced using natural materials for most of their history, until the chemical synthesis industry began in the late 19th and early 20th centuries, creating the first man made dyes on a mass scale. Synthetic dyes can be split into two broad categories – those that are compatible with water, and those that are compatible with oil and other organic solvents, AKA solvent dyes.

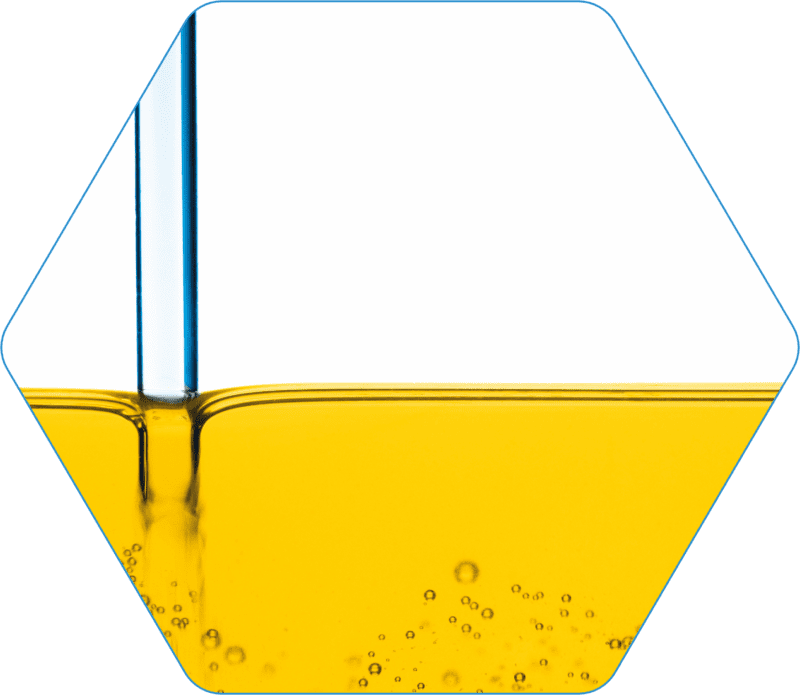

Solvent dyes are non-polar organic compounds which are soluble in oil-based liquids. They are used in many industries because they give vibrant and lasting colour to materials that are not water compatible. Versatile and durable, solvent dyes are used in various applications including fuels, lubricants, waxes, paints, and many others.

The upsides and downsides of using powder solvent dyes

Solvent dyes were originally manufactured as powders, containing solid versions of the dye chromophore; the core chemical structure which dictates the dye colour by absorbing certain wavelengths of light. The manufacturing processes of powders are strictly controlled to achieve this, including multiple separation, filtering, and drying stages with little contact with air or water. As a result, they are very high in purity and generally do not contain more than one substance.

Being a single substance with very high purity levels has several benefits. When kept in appropriate storage conditions, powders are stable over a long period of time. Up to 5 years or more in most cases. The concentration of powder dyes is very high, so they can be used at low dosage rates to achieve a high colour strength.

Being a single substance with very high purity levels has several benefits. When kept in appropriate storage conditions, powders are stable over a long period of time. Up to 5 years or more in most cases. The concentration of powder dyes is very high, so they can be used at low dosage rates to achieve a high colour strength.

As with anything, there are some downsides. Powders are hard to handle. They have negative implications for health and safety since they are easily inhaled, so sophisticated PPE systems such as respirators are required to protect workers.

Most countries follow combustible powder regulations, which require ATEX rated equipment, dust management systems, local exhaust ventilation and more, to prevent dust build up and to control ignition sources. Large investments in infrastructure may be required for companies that don’t routinely handle powders.

Finally, dosing powders into manufacturing processes can be challenging. When adding them into liquids, powders need to be fully dissolved or mixed in, which can be difficult to achieve in fuels and other solvents. Many companies will use an additional manufacturing step, such as premixing the powders with an aromatic solvent, before adding into the full manufacturing process, leading to increased production time and cost. Especially if additional heat and agitation is required.

The pro’s and con’s of using liquid solvent dyes

If you don’t want to deal with the manual handling, exposure risks and difficulty in using powder solvent dyes, liquid versions may be a better option.

Liquid solvent dyes are manufactured by adding longer functional groups to the dye chromophore, increasing their solubility in organic solvents. Final products often use mixtures of the same chromophore with different functional groups to improve solubility further but retain the dye colour. This makes them more suitable than powder dyes for fuels, most lubricants, and most other hydrocarbon-based liquids.

The main advantages of liquid solvent dyes are the lower exposure risk and ease of handling. Liquids do not generate dust, so not only is the risk of inhalation extremely low, but combustible powders regulations do not apply. They can also be added into manufacturing processes directly from storage tanks or drums, without any contact with the operator.

The main advantages of liquid solvent dyes are the lower exposure risk and ease of handling. Liquids do not generate dust, so not only is the risk of inhalation extremely low, but combustible powders regulations do not apply. They can also be added into manufacturing processes directly from storage tanks or drums, without any contact with the operator.

Liquids are easier to manage and use than powders. They can be shipped in a wider variety of pack types, and stored in high volumes within storage tanks, giving more flexible options for logistics and storage. They can be blended straight into final products, avoiding an additional manufacturing step (depending on application), saving time and money.

However, liquids do have some downsides. The shelf life is shorter at 2 years, and the standard dosage rate is higher at 20mg/L (again depending on application). Finally, liquid dyes can generate different hazard phrases than powders due to the hydrocarbon solvents used in the final formulations, so are more expensive to ship by volume.

Our recommendations for your industry and application

There are advantages to using both liquid or powder solvent dyes , and the appropriate product depends on the end application and your manufacturing setup.

In situations where the end product is very viscous, powders remove unwanted interactions with organic solvents present in their liquid counterparts and require small dosages to achieve a strong colour. If there are restrictions on toxicity and hazard phrases relating to organic solvents, some powders can again be the better option.

This includes applications such as epoxy resin, home care products, high viscosity lubricants, adhesives, cosmetics, plastic master batch, candles, explosives and more. However, because of the significant advantages in ease of use and lower exposure risk, we recommend liquid solvent dyes for most other applications, including fuels, lubricants, hydraulic oils, ATF, non-destructive testing and more.

This includes applications such as epoxy resin, home care products, high viscosity lubricants, adhesives, cosmetics, plastic master batch, candles, explosives and more. However, because of the significant advantages in ease of use and lower exposure risk, we recommend liquid solvent dyes for most other applications, including fuels, lubricants, hydraulic oils, ATF, non-destructive testing and more.

Whatever your colour requirements, technical specification, handling needs, industry or application, John Hogg can deliver a speciality dye solution to match. Our lower – naphthalene (NF) range includes high-quality, vibrant liquid solvent dye options that help to reduce manual handling risks and health hazards, without compromising on performance.

For more information on which dye product is the right one for you, please get in touch using the contact us page.